APPLICATION

- The FLUID SOLAR pumps have been developed to pump clean water from a well utilising energy obtained from photovoltaic panels. The electronic control incorporated into the high performance motor converts the exit voltage from the panels and regulates the velocity of rotation of the motor in order to utilise the available energy most efficiently at any one time: on a sunny day there will be a high velocity of rotation with a raised performance of the pump, and on a cloudy day the velocity and the performance will be reduced. It can handle liquids with a maximum temperature of 35 °C and a maximum sand content of 150 g/m³. The pump can be installed both vertically and horizontally, and it has a maximum immersion depth of 40 m when used with a sufficiently long power cable. The construction of the pump consists of several components. The delivery body and external sleeve are made of stainless steel AISI 304 and have a threaded delivery port in compliance with ISO 228/1. The impellers are made of Lexan 141-R for FLUID SOLAR 1/10, 4/4, 6/3 models, and Delrin for FLUID SOLAR 2/6 model. The diffusers are made of Noryl FE1520PW. The stage boxes and stage lids are constructed with stainless steel AISI 304. A stainless steel AISI 304 cable cover is also included. The pump shaft is made of stainless steel AISI 304 for FLUID SOLAR 1/10, 4/4, 4/8, 6/3 models, while the drive coupling is made of stainless steel AISI 316L for the same models. The motor shaft is made of stainless steel AISI 431, and the motor sleeve is made of stainless steel AISI 304. The pump features two mechanical seals separated by an oil chamber. The seal model for the motor side is STA-17 with a shaft diameter of Ø 17 mm, while the seal model for the pump side is ST1-16 with a shaft diameter of Ø 16 mm. The materials used for the stationary ring are silicon carbide, and for the rotational ring, graphite. The elastomer used is NBR.

FEATURES

- Maximum liquid temperature +35 °C

- Maximum sand content 150 g/m³

- Maximum immersion depth of 40 m with a sufficiently long

- power cable

- Installation:

- vertical

- horizontal

CONSTRUCTION

- POS. COMPONENT CONSTRUCTION CHARACTERISTICS

- 1 DELIVERY BODY AND EXTERNAL SLEEVE Stainless steel AISI 304 complete with threaded delivery port in compliance with ISO 228/1.

- 2 IMPELLERS Lexan 141-R for FLUID SOLAR 1/10, 4/4, 6/3 Delrin for FLUID SOLAR 2/6

- 3 DIFFUSERS Noryl FE1520PW

- 4 STAGE BOXES / STAGE LIDS Stainless steel AISI 304

- 5 CABLE COVER Stainless steel AISI 304

- 6 PUMP SHAFT Stainless steel AISI 304 for FLUID SOLAR 1/10, 4/4, 4/8, 6/3

- 7 DRIVE COUPLING Stainless steel AISI 316L for FLUID SOLAR 1/10, 4/4, 4/8, 6/3

- 8 MOTOR SHAFT Stainless steel AISI 431

- 9 MOTOR SLEEVE Stainless steel AISI 304

- 10 TWO MECHANICAL SEALS SEPARATED BY AN OIL CHAMBER

- Seal Model STA-17 ST1-16

- Shaft Diameter Ø 17 mm Ø 16 mm

- Position Motor side Pump side

- Materials

- Stationary ring Silicon carbide Silicon carbide

- Rotational ring Graphite Graphite

- Elastomer NBR NBR

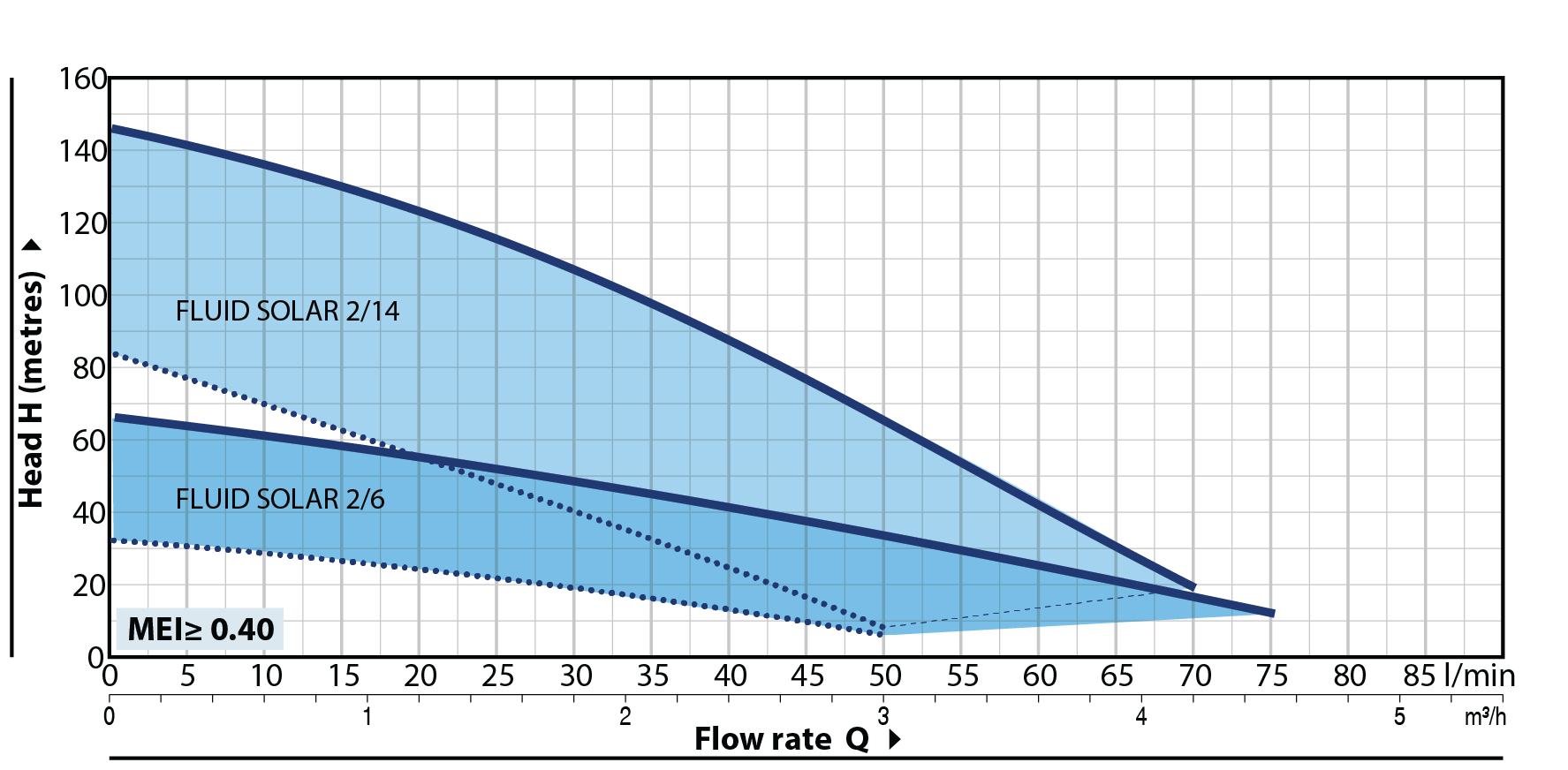

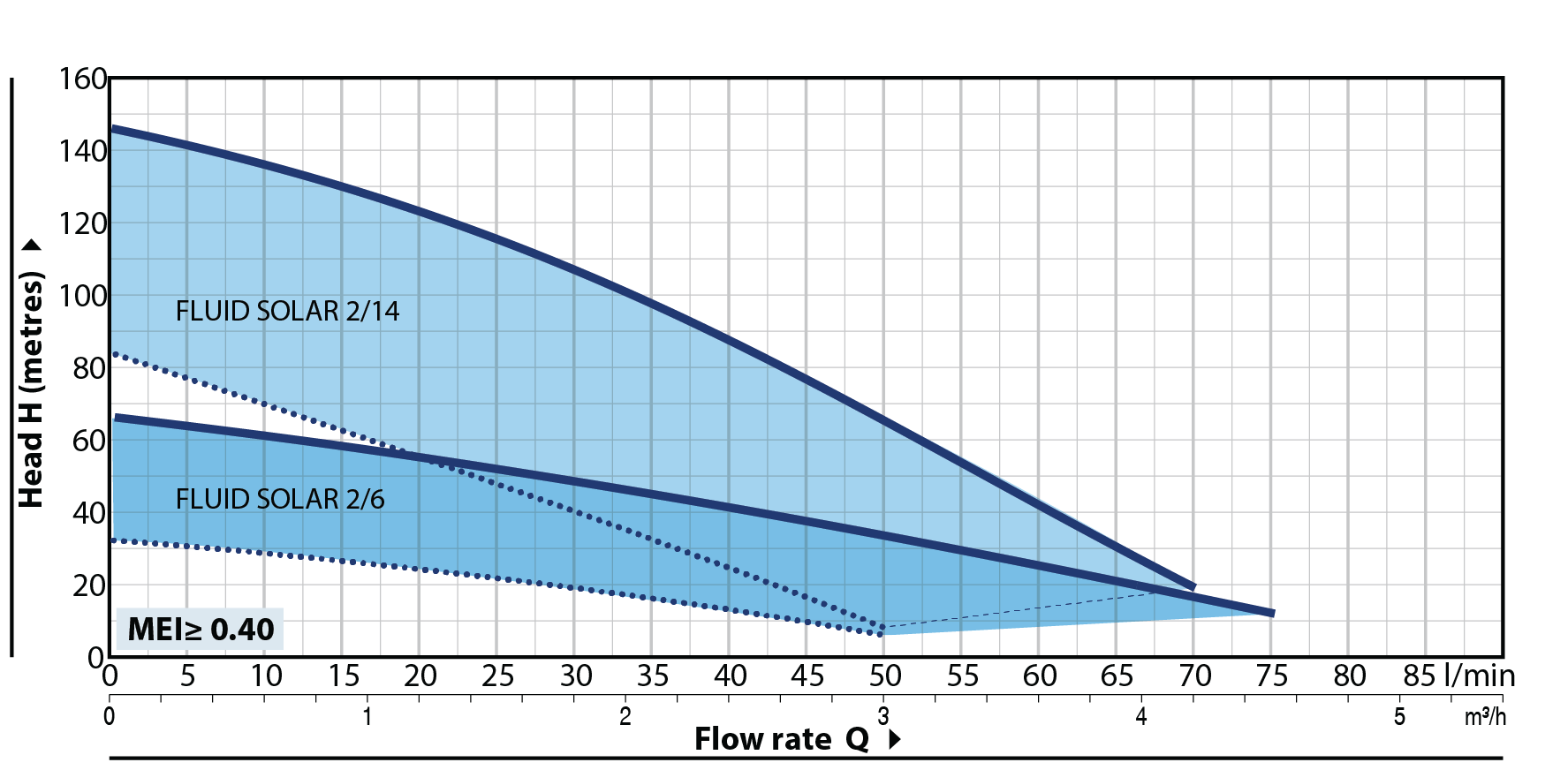

FLUID-SOLAR-24-214-2

FLUID-SOLAR-24-214-3

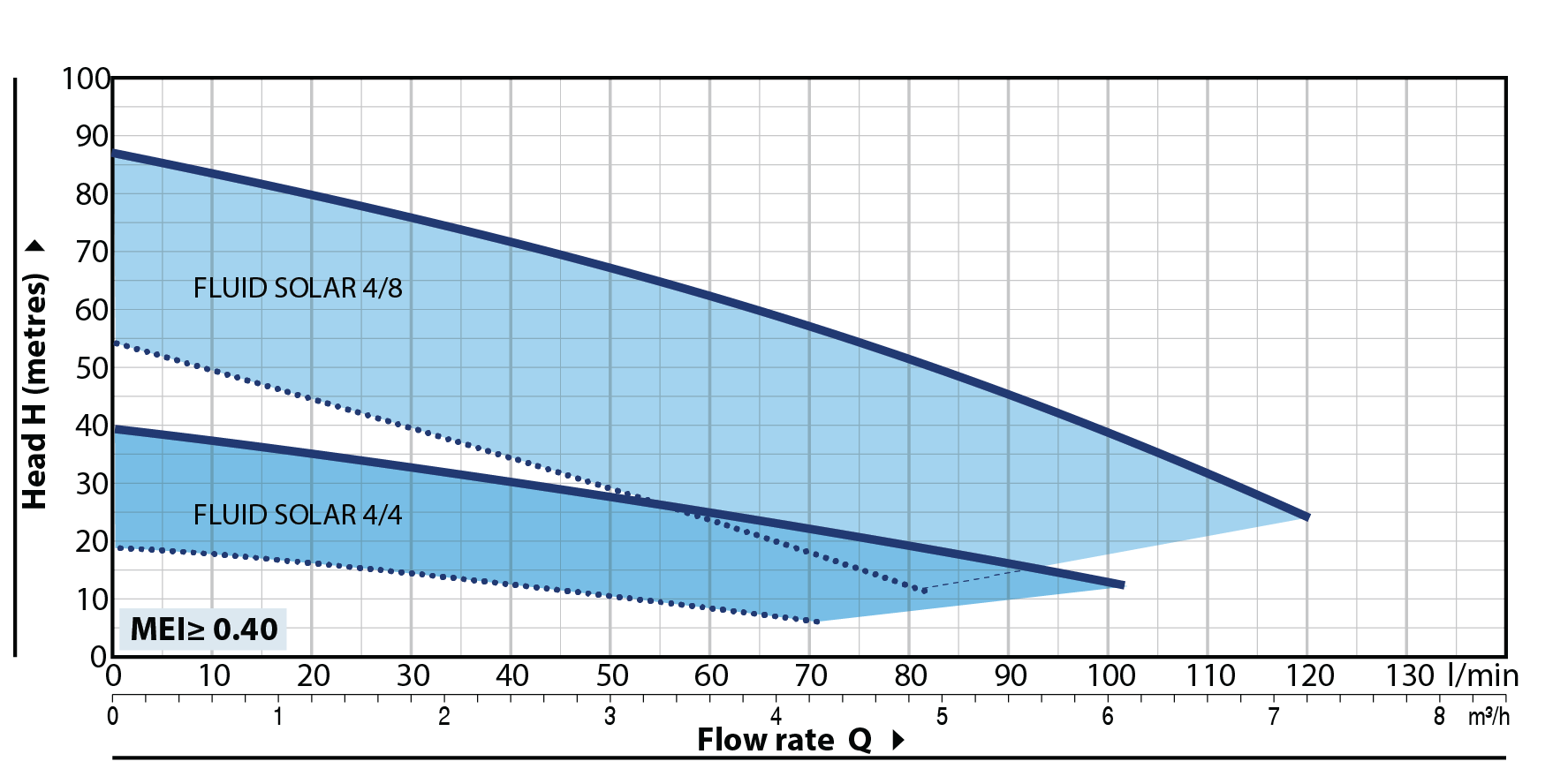

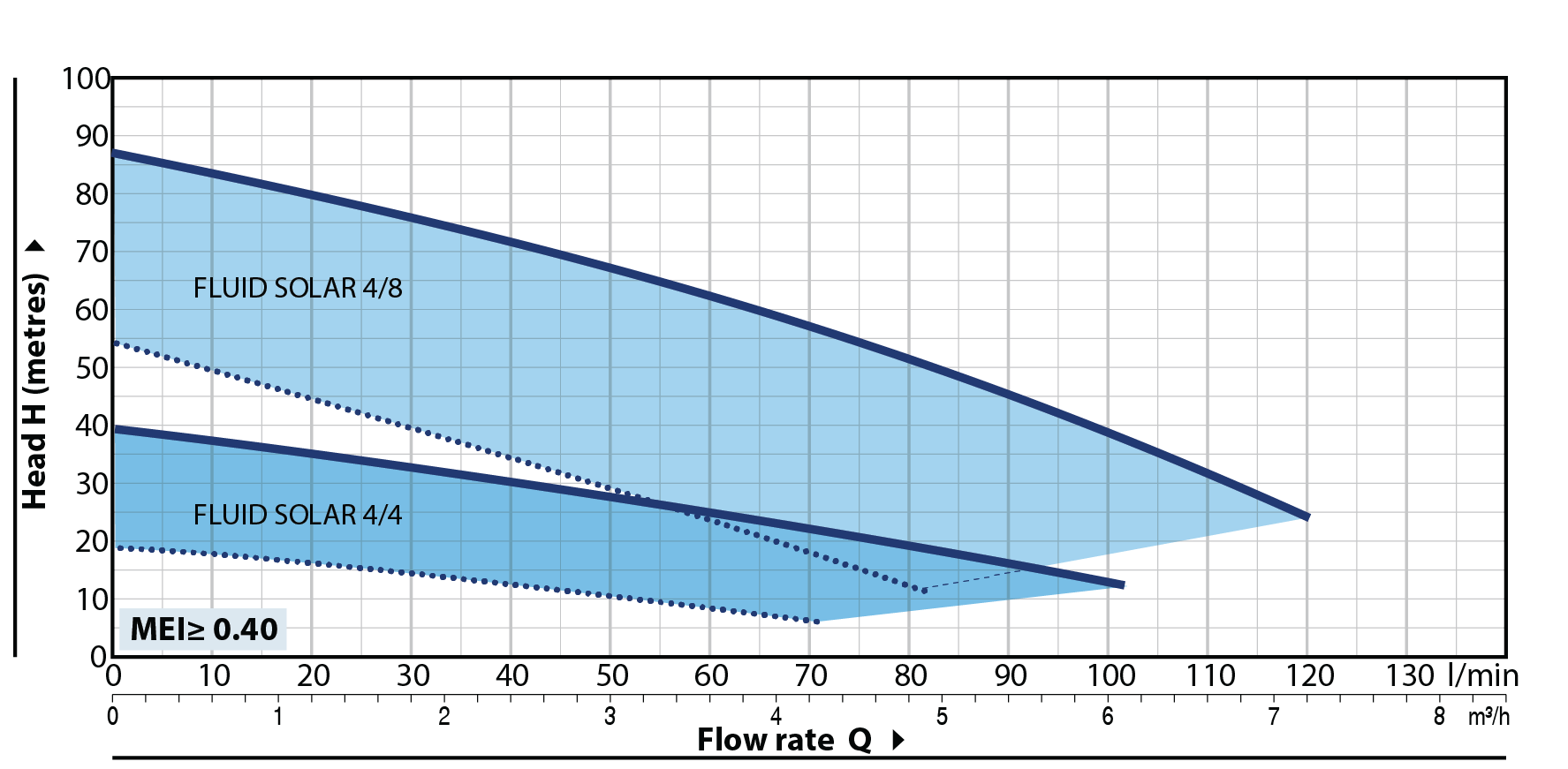

FLUID-SOLAR-44-48-2

FLUID-SOLAR-44-48-3

Technical Data

| Pump Model | Power

(kW) (HP)

|

Max Flow

(L/min) |

MAX HEAD

(m) |

Connection

Outlet (mm) |

Water Temp

Inlet |

Size (mm)

Height / Length / Width |

GW | Origin | Sub Category 1 Description | Sub Category 2 Description | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FLUID-SOLAR-2-6 | 0.75 | 75 | 64 | 25 | 35°C | 587 | 100 | 11.4 | /Made-in-Italy-Icon.png | Pedrollo Solar Bore Pumps | Pedrollo Solar Bore Pumps | ||

| FLUID-SOLAR-2-14 | 1.5 | 70 | 140 | 25 | 35°C | 855 | 100 | 13.8 | |||||

| FLUID-SOLAR-4-4 | 0.75 | 100 | 38 | 25 | 35°C | 614 | 100 | 11 | |||||

| FLUID-SOLAR-4-8 | 1.5 | 120 | 85 | 25 | 35°C | 772 | 100 | 13.7 | |||||